VOCs and NOx Gas Treatment Facility

- VOCs & NOx Gas Treatment System

- Based on rich and diverse experiences and performances, EST provides the best solution for air pollution gas.

VOCs Treatment Facility

- VOCs (volatile organic compounds) are representative air pollutant substances and substance itself is toxic. This technology converts and treats VOCs by oxidizing VOCs into CO2 and H2O with high-temperature heat or catalyst.

Regenerative Combustion Facility (Regenerative Thermal Oxidizer)

- - Regenerative combustion facility oxidizes VOCs and organic foul smelling gas in high temperature (750~850°C).

- - The high-efficiency energy saving facility recovers the waste heat generated after incineration in high heat recovery efficiency over 95% by using ceramic heat storage.

Regenerative Catalytic Combustion Facility (Regenerative Catalytic Oxidizer)

- - This technology utilizes regenerative combustion facility. It remarkably reduces operation cost while keeping the efficiency of existing facility.

- - Regenerative catalytic combustion facility is the energy saving facility that runs in remarkably low temperature of 350 °C and uses catalyst to reduce the activation energy consumed during combustion of VOCs gas.

Applications

- Applicable on chemical process, printing industry, semiconductor industry, electronic product manufacturing factory, etc.

NOx Treatment Facility

- NOx treatment facility injects a reducing agent (NH2, etc.) on gas generated from NO and NO2 to convert and treat into harmless N2 and H2O through high-temperature heat or catalyst.

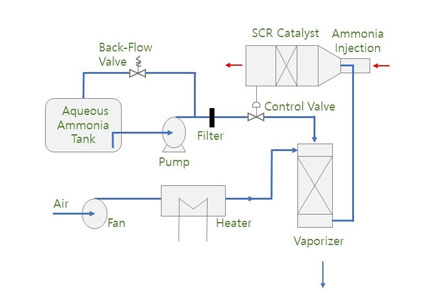

SCR (Selective Catalytic Reduction)

- - This facility injects a reducing agent on gas including NOx, make it pass through catalyst layer, and reduces NOx efficiently in temperature of 250~400°C to treat NOx.

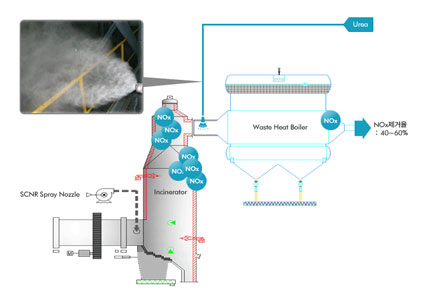

SNCR (Selective Non-Catalytic Reduction)

- - This facility sprays a reducing agent inside the hot furnace and NOx gas does not go through the catalyst layer. It reduces NOx in the efficiency rate of 40~60% to treat NOx.

- - This facility is used on furnaces that don’t need high-efficiency nitrogen reduction. This NOx reduction technology is easy to install and cost effective.

Treatment Process

- 4NO + 4NH3 + O2 → 4N2 + 6H2O

- 6NO2 + 8NH3 → 7N2 + 12H2O

Applications

- Applicable on nitric acid production factory, power plant, industrial boiler, back part of domestic waste and specific waste furnace, etc.